|

Search: |

|

Search: |

HOME → ARTICLES → Eco-Conscious Pressure-Assisted Casting Machine

President

CMH Manufacturing Company

www.cmhmfg.com

Whether you call it being “green,” eco-conscious, environmentally friendly or simply reducing your carbon footprint—everyone realizes that today’s foundries need to reduce costly waste streams along with high energy costs to make cost competitive castings.

The bottom line is that being competitive requires both energy and material efficiencies combined with protecting the environment. Reducing energy usage in the foundry is critical to lowering casting costs. The old thinking was that it was too costly to reduce your environmental impact. Today’s newer technologies are making it easier to reduce energy costs and environmental impact at the same time.

It is well known to all in our industry that metal casting is one of the most energy-intensive industries in the US, as you need large amounts of electrical and heat energy just to melt metals. High energy consumption is so important to this industry, that most foundries typically undertake an energy audit to understand their costs to help identify ways to reduce their consumption.

While this industry has always used recycled metal to produce new castings, there are plenty of other by-products that have ended up in landfills – increasing disposal costs which results in reduced profits, and of course increased overall environmental impact. The casting process generates many types of waste: most notably, spent sand, combustion, and hydraulic fluid/lubricant waste.

Foundry equipment by design is built tough. It has to be in order to endure the demanding and harsh foundry environment. However, as technology continues to improve this heavy-duty equipment, it is being designed to make more efficient use of materials, reduce energy, and reduce waste, which in turn reduces disposal costs and increases profit margins.

The challenges to having a sustainable and successful foundry in the USA are plentiful. Between staffing and supply chain issues, everyone has their hands full. But the opportunity, especially now—to encourage reshoring of castings—provides strong incentive for evaluating processes (often with value stream mapping) to identify areas of waste, and energy audits to really understand how much energy is costing your foundry.

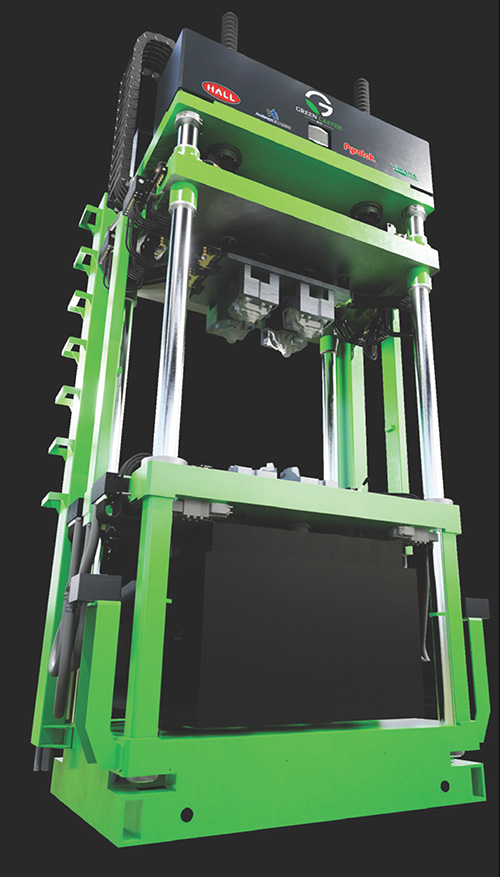

To overcome these challenges, we look to equipment technology and design to effectively make the entire process more cost efficient and compliant to environmental concerns. We recently introduced an industry-first pressure-assisted casting system with these specific goals.

LOWER ENERGY CONSUMPTION

In this new equipment, roller screw technology is used instead of hydraulic pumps to allow safer, faster, less energy dependent movement of the upper platen. Also, flash detection on the parting line, leak prevention, adaptive (intelligent) mold closing for applying appropriate clamp force to reduce the mechanical stress in the mold and prolong its life.

Current low-pressure casting machines use large hydraulic pumps using high amounts of electrical power–12 kW or more. Additionally, their duty cycle is longer—using double the electrical consumption. The substantial energy savings with the elimination of hydraulic pumps is truly amazing—as the average electrical consumption (without the furnace) is about 5 kWh with this new pressure-assisted casting system.

To reduce furnace energy consumption, horizontal immersion heaters are used to minimize the generation of oxides. This reduces furnace energy consumption dramatically. The large, bonded particle filter separates the charge area from the pump chamber. The bonded particle filters prevent the resuspension of oxides by reducing the metal velocity, helping to make higher quality castings.

REDUCE WASTE

Eliminating hydraulic cylinders means no costly oil / hydraulic fluid waste disposal. It also means no compressed air is needed, further reducing casting costs.

HIGHER QUALITY

Incorporating a precision pump ensures flow rate and pressure profile to properly fill the mold. Eliminating compressed air to move the metal into the mold increases metal quality. The precision casting pump uses a float attached to the ceramic foam filter on the bottom of the pump to provide a secondary filtration of the metal. The filter separates when it’s lifted from the bath.

The ability of the pump system to hold metal at a consistent level very close to the mold reduces oxide buildup inside the riser tube. The overall temperature of the pump is less, which impacts the amount of shrink in the casting— and a significant advantage over low pressure casting systems in regard to producing higher quality castings.

HIGHER ACCURACY

Replacement of the hydraulic actuators with electrical actuators in all units provides real time measuring of the stroke and force with higher accuracy 0.05mm and 1kN increments.

Being competitive on a global scale is only getting harder. It’s time to look at your equipment to reduce high energy and maintenance costs while reducing disposal costs.

Global automotive, aerospace, electronics, and consumer companies are routinely asking foundries to detail their sustainability plans. This type of equipment easily meets all of the benchmarks for a strong sustainability initiative. To begin the process, conduct your own energy audits to know how impactful these new equipment innovations will be to both the bottom line and global competitiveness.

Check back

soon for more

information.