|

HOME → PRODUCTS → Reverse Tilting Machines → RT3 Reverse Tilting Permanent Mold Casting Machine

RT3 Reverse Tilting Permanent Mold Casting Machine

Features

- Low maintenance due to few moving parts, heavy duty, rugged, and dependable.

- Unique design allows the mold to be poured while the parting line is perpendicular to the floor. The machine tilts the mold so that the parting line is parallel to the floor for solidification and ejection.

- Cushioned tilt cylinders provide a smooth tilting motion from start to stop.

Specifications

Clamping pressure |

29,500 lbs. |

(13,381 kg.) |

Max. mold size |

33 x 20 in. |

(84 x 51 cm) |

Max. mold weight |

1,800 lbs |

(816.5 kg.) |

Ram stroke |

18 in. |

(46cm) |

Daylight opening |

21 in |

(53.4 cm) |

Machine weight |

3,800 lbs |

(1,724 kg.) |

Tilt speed |

7 sec. |

|

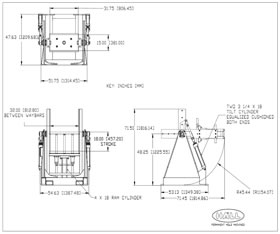

Click to enlarge.

The drawing (above) requires Adobe Acrobat Reader to view.

Videos

RT3 Reverse Tilt-Pour Permanent

Mold Casting Machine Animation

Ejection Position

Pouring Position

|